Design a Pepper Seed Drying Oven with a Capacity of 8-10 (kg/hour)

##plugins.themes.academic_pro.article.main##

Abstract

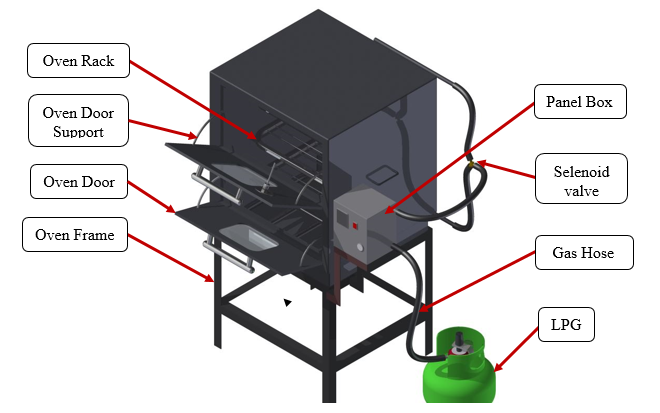

The drying process of pepper seeds is still done by relying on sunlight, whereas rainy weather conditions will greatly slow down drying. Drying using an oven is done to make the pepper cleaner from dirt and efficient against the time of drying the pepper, For this reason, an oven is needed to dry pepper seeds so as not to be too dependent on weather conditions. This oven heating system uses LPG gas, a hygrometer used to estimate temperature and humidity, and a thermostat to regulate the room temperature in the oven, also equipped with an automatic lighter to make it easier to start the fire in the oven. The dried peppers that have been tested ranging from 50°C, 60°C, 70°C, 80°C, and 90°C are all dry with the longest duration of 99 minutes and the fastest time of 15 minutes.

##plugins.themes.academic_pro.article.details##

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

[2] P. M. U. Biji-bijian, “Rancang Bangun Mesin Pengering Vertikal Dengan Pengadukan Mekanik Untuk Biji-Bijian,” pp. 107–114, 2009.

[3] A. Hardiansyah, D. Bakce, and D. Tety, “Analisis keunggulan komparatif lada Indonesia di pasar internasional,” Pekbis J., vol. 7, no. 2, pp. 85–93, 2015.

[4] A. Muhammad, A. Mukhlis, E. Hartulistiyoso, and Y. A. Purwanto, “Pengaruh Kadar Air terhadap Beberapa Sifat Fisik Biji Lada Putih Effect of Moisture Content on Some Physical Properties of White Pepper Seeds,” Agritech, vol. 37, no. 1, pp. 15–21, 2017.

[5] R. Sutamihardja, N. Yuliani, and O. Rosani, “Optimasi Suhu Pengeringan Dengan Menggunakan Oven Terhadap Mutu Lada Hitam Dan Lada Putih Bubuk,” J. Sains Nat., vol. 8, no. 2, p. 80, 2018.

[6] A. E. Erviani, A. R. Arif, and N. F. Nisa, “Analisis Rendemen dan Skrining Fitokimia Ekstrak Cacing Laut Eunice siciliensis,” J. Ilmu Alam dan Lingkung., vol. 10, no. 1, pp. 1–6, 2019.

[7] R. Anggraini, A. Jayuska, and A. H. Alimuddin, “Lada hitam (Piper nigrum L.) Asal Sajingan Kalimantan Barat,” J. Kim. Khatulistiwa, vol. 7, no. 4, pp. 124–125, 2018.

[8] D. santoso Deny Murdianto, “Pemodelan Mesin Pengering Biji - Bijian Tipe Batch Menggunakan Hybrid Petri Net,” Pertan. Berkelanjutan, vol. 7, no. 2, pp. 115–120, 2019.

[9] N. Nurdjannah and Hoerudin, “Pengaruh Perbandingan Berat Buah Lada Dengan Air dan Waktu Pemblansiran terhadap Mutu Lada Hitam yang Dihasilkan,” Teknol. Pasca Panen, vol. 3, no. 1, pp. 59–65, 2007.

[10] A. J. Nazar, Analisis Perpindahan Panas Pada Oven Untuk Proses Pengeringan Jamur Tiram. Surabaya: Institut Teknologi Sepuluh November, 2014.

[11] A. Prasetyaningrum, “Rancang Bangun Oven Drying Vaccum Dan Aplikasinya Sebagai Alat Pengering Pada Suhu Rendah,” Riptek, vol. 4, no. 1, pp. 45–53, 2010.

[12] Ramadhani Widyastuti, “Pengeringan Lapisan Tipis Irisan Singkong Menggunakan Pengering Oven Dengan Variabel Waktu dan Humidity Terhadap Laju Pengeringan,” Universitas Diponegoro Semarang, 2017.

[13] D. Suryana, “Perekayasaan Oven Pengering Rengginang Dengan Menggunakan Bahan Bakar Sabut Kelapa Dan Gas LPG,” Din. Penelit. Ind., pp. 94–101, 2020.

[14] R. Andriyono, “Rancang Bangun Mesin Pengering Lada Dan Kemiri (Dryer),” Ilm. Mustek Anim Ha, vol. 5, pp. 246–257, 2016.

[15] Setiyo, “Pengaruh Temperatur Terhadap Laju Pengeringan Jagung Pada Pengeringan Konvensional Dan Fluidized Bed,” Poros, vol. 15, no. 2, pp. 101--118, 2003.