Cogeneration Analysis of Krebet Baru II Sugar Factory Milling Capacity

##plugins.themes.academic_pro.article.main##

Abstract

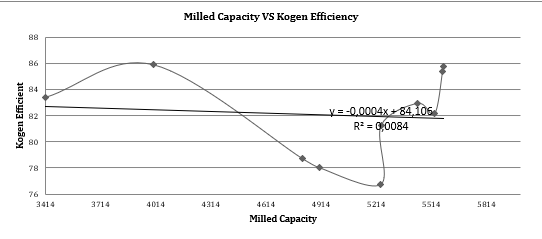

Sugar producers can extend their sugar companies by expanding into non-sugar products. A sugarcane-based company that focuses on product diversification is electricity generation from bagasse. As the principal energy source, the cogeneration system progressively creates two distinct forms of energy (mechanical energy and thermal energy). Krebet Baru 2's sugar factory has a capacity of 5,200 TCD. Under some conditions, it can generate up to 1.5 MW of additional Power. This research aims to investigate the link between capacity and cogeneration efficiency. As a result, extra electricity may be generated forever. According to the data, capacity did not influence cogeneration efficiency. Excess Power may be acquired by optimizing steam usage, assessing inefficient energy sources, and utilizing high-pressure steam production facilities.

##plugins.themes.academic_pro.article.details##

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

[2] S. Harnowo, A. Hidayat, and R. Gupta, “Applied energy and mass balance optimization re-engineering: case on Industri Gula Glenmore, Ltd.,†J. Eng. Appl. Technol., vol. 3, no. 2, pp. 64–72, 2022, doi: 10.21831/jeatech.v3i2.52403.

[3] F. R. Rifai and A. Prasetya, “Potensi Energi Terbarukan Dari Sistem Kogenerasi di Pabrik Gula Studi Kasus Potensi Energi Terbarukan Dari Sistem Kogenerasi di Pabrik Gula Studi Kasus Pabrik Gula Gempolkrep , Mojokerto , Jawa Timur,†no. April 2020, 2015.

[4] S. Chantasiriwan, “Improving energy efficiency of cogeneration system in cane sugar industry by steam dryer,†Chem. Eng. Trans., vol. 87, no. January, pp. 511–516, 2021, doi: 10.3303/CET2187086.

[5] R. Ahmad, “Bagasse Based High Pressure Co-Generation in Pakistan,†IOSR J. Mech. Civ. Eng., vol. 13, no. 2, pp. 27–32, 2016, doi: 10.9790/1684-1302012732.

[6] A. Khoodaruth, “Optimisation of a cogenerated energy systems: The cane biomass flexi-factory case study,†Energy Procedia, vol. 62, pp. 656–665, 2014, doi: 10.1016/j.egypro.2014.12.429.

[7] M. J. B. Kabeyi and O. A. Olanrewaju, “Performance analysis of a sugarcane bagasse cogeneration power plant in grid electricity generation,†Proc. Int. Conf. Ind. Eng. Oper. Manag., no. 2011, pp. 1048–1061, 2021.

[8] E. Birru, C. Erlich, and A. Martin, “Energy performance comparisons and enhancements in the sugar cane industry,†Biomass Convers. Biorefinery, vol. 9, no. 2, pp. 267–282, 2019, doi: 10.1007/s13399-018-0349-z.

[9] M. Alves, G. H. S. F. Ponce, M. A. Silva, and A. V. Ensinas, “Surplus electricity production in sugarcane mills using residual bagasse and straw as fuel,†Energy, vol. 91, pp. 751–757, Nov. 2015, doi: 10.1016/j.energy.2015.08.101.

[10] M. Hiloidhari, R. Banerjee, and A. B. Rao, “Life cycle assessment of sugar and electricity production under different sugarcane cultivation and cogeneration scenarios in India,†J. Clean. Prod., vol. 290, p. 125170, Mar. 2021, doi: 10.1016/J.JCLEPRO.2020.125170.

[11] S. Chantasiriwan, “Improving energy efficiency of cogeneration system in cane sugar industry by steam dryer,†Chem. Eng. Trans., vol. 87, no. January, pp. 511–516, 2021, doi: 10.3303/CET2187086.

[12] A. V. Ensinas, S. A. Nebra, M. A. Lozano, and L. Serra, “Analysis of cogeneration systems in sugar cane factories - Alternatives of steam and combined cycle power plants,†ECOS 2006 - Proc. 19th Int. Conf. Effic. Cost, Optim. Simul. Environ. Impact Energy Syst., no. June 2014, pp. 1177–1184, 2006.

[13] G. S. Yarnal and V. S. Puranik, “Industry Using System,†Cogener. Distrib. Gener. J., vol. 24, no. 3, pp. 7–22, 2009.