Effect of Accelerator Addition on the Drying Time, Thickness and Glossy Clear Coat in Vehicle’s Body

##plugins.themes.academic_pro.article.main##

Abstract

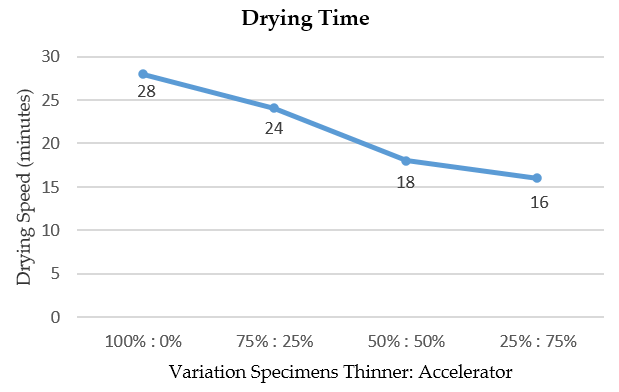

Painting is the application of paint in liquid form onto the object, to create a thin layer which is then dried to form a hard layer or layers of paint. Many things are influential in the painting process, including the clear coat process which functions as a gloss effect and protects and maintains the paint color of the vehicle. In this research, it was expected to know the effect of the ratio between the thinner and accelerator on the clear coat on drying time, thickness, and glossiness of the clear coat. In this study, the mixture ratio variations of accelerator and thinner used were 0%: 100%, 25%: 75%, 50%: 50%, 75%: 25%. The speeds of drying with the aforementioned ratio of accelerator and thinner were 28 mins, 24 mins, 18 mins, and 16 mins respectively, while the values of the thickness of the ratio were 53, 4 µm, 55.6 µm, 54.03 µm, and 57.1 µm respectively, and the glossiness values of the accelerator and thinner with the ratio were 96.1 Gu, 95.4 Gu, 92.5 Gu, and 93.1 Gu respectively.

##plugins.themes.academic_pro.article.details##

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

[2] A. KHASIB, “Pengaruh Variasi Penggunaan Thinner Pada Campuran Cat Terhadap Kualitas Hasil Pengecatan,†J. Pendidik. Tek. Mesin UNESA, vol. 6, no. 01, p. 250865, 2017.

[3] F. Y. Utama, Teknologi Pengecatan Kendaraan Bermotor, 1st ed., no. September. Surabaya: Universitas Negri Surabaya, 2018.

[4] D. Setyawan and F. Utama, “Pengaruh Komposisi Mixing Clear Gloss (Vernish) Terhadap Kualitas Hasil Pengecatan Pada Komponen Bodi Kendaraan,†JPTM., vol. 6, no. 01, pp. 63–67, 2017.

[5] S. T. Dwiyati, “Pengaruh Kadar Hardener Terhadap Kualitas Produk Pengecatan Plastik,†J. Konversi Energi dan Manufaktur UNJ, vol. II, pp. 65–72, 2015.

[6] F. I. Permana and S. Anwar, “Pengaruh Kualitas Thinner Pada Campuran Cat Terhadap Hasil Pengecatan,†JTM., vol. 03, no. 02, pp. 53–61, 2014.

[7] M. A. Ramdhoni, “Pengaruh variasi temperatur dan accelerator asam nitrit pada proses phospating di aplikasi powder coating mild steel ST 37,†UNIVERSITAS JEMBER, 2015.

[8] D. Stoye and W. Freitag, Paints, Coatings and Solvents, 2nd ed. Germany: Weinheim, 1998.

[9] M. W. Ardyanto and F. Y. Utama, “Rekayasa Komposisi Mixing Solvent Dan Varnish Terhadap Kualitas Hasil Pengecatan Menggunakan Gloss Meter,†vol. 07, pp. 26–33, 2018.

[10] N. J. Habibie and S. Anwar, “Pengaruh Perbandingan Campuran Cat Dengan Thinner Terhadap Kualitas Hasil Pengecataan,†Jtm, vol. 2, no. 3, pp. 97–104, 2014.

[11] K. B. Hermianto and F. Y. Utama, “Pengaruh Drying Process Terhadap Finishing Top Coat Pada Pengecatan,†Pengaruh Dry. Process Terhadap Finish. Top Coat Pada Pengecatan, vol. 06, pp. 215–224, 2018.

[12] S. Sukram and S. Sutikno, “Pengaruh Suhu Dan Waktu Tinggal Terhadap Kecenderungan Menguning Pada Proses Produksi Alumunium Fasad,†JATI UNIK J. Ilm. Tek. dan Manaj. Ind., vol. 2, no. 1, p. 64, 2019, doi: 10.30737/jatiunik.v2i2.330.

[13] F. PRANATA, “Perbaikan Bodi Dan Pengecetan Mobil Ford Telstar Tahun 1986 AB 1073 MA Bagian Setengah Atap Belakang Dan Belakang,†UNIVERSITAS NEGERI YOGYAKARTA, 2012.

[14] Team B&P, Pedoman Pelatihan Pengecatan, 2nd ed. Jakarta: PT. Toyota - Astra Motor, 2015.