Salwa Cars Structure Testing Standards Regulation Formula Society of Automotive Engineers

##plugins.themes.academic_pro.article.main##

Abstract

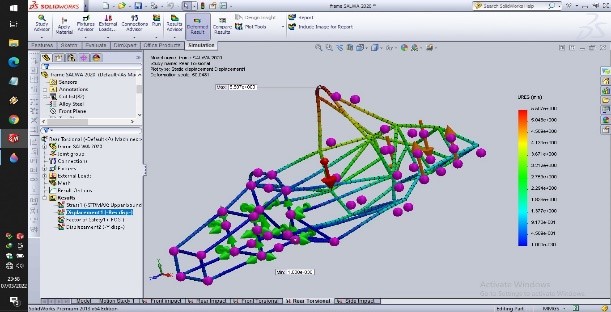

This research was to find out the results of the bending and torsional stiffness testing of the SALWA car according to Formula SAE 2021 regulations. The research method was by designing through Solidworks 2014 software. Testing of test specimens referred to Formula SAE 2021 regulations. The front impact test results produced max Von Mises 1046.921 MPA with a displacement of 8,540 mm; the rear impact test resulted in a max Von Mises of 222,529 MPa with a max displacement of 6.85 mm; and the side impact test resulted in max Von Mises Stress of 104.15 MPa with a max displacement of 9,116 mm. In the front torsional test, the max Von Misses Stress reached 135,266 MPa with a total max displacement of 4,844 mm. The rear torsional test had a max Von Mises Stress value of 147,144 MPa with a displacement of 5.51 mm. The feasibility test still found connection and construction placement errors, and there was a low Factor of Safety value. In conclusion, the construction of the SALWA Electric Car prototype frame is not in accordance with Formula SAE regulations.

##plugins.themes.academic_pro.article.details##

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

[2] Ilhami, A. H., Analisis Collision Pada Chassis Formula SApuangin Speed Dengan Material Aluminium Menggunakan Metode Elemen Hingga. Surabaya: Institut Teknologi Sepuluh Nopember, 2016.

[3] D Jatmoko and Y Setyo, “Development of The Learning Sign System Media to Improve The Result Learn of Students Light Vehicle Engineering Competence,†Int. Conf. Educ., 2017.

[4] M. Kashikar, A S., “Design And Analysis Of Formula Car,†Int. J. Res. Publ. Eng. Technol., vol. 2, no. 1–5, 2017.

[5] International, S., Formula SAE Rules 2021. World: SAE International., 2020.

[6] Salafuddin, H, “Pada Rangka Kendaraan Jenis Prototype Sesuai Standar Shell Eco Marathon Asia.,†Jkt. Univ. Negeri Jkt., 2016.

[7] Khoiron, M. S., “Perbandingan Kekauan Dan Kekuatan Chassis Dan Body Kendaraan Yang Tebuat Dari Material Aluminium Dan Carbon Fiber Terhadap Beban Vertikal Dan Torsional Bending,†Institut Teknologi Sepuluh Nopember, Surabaya, 2016.

[8] Sadikin, A, “Perancangan Rangka Chasis Mobil Listrik Untuk 4 Penumpang Menggunakan Software 3D Siemens NX8,†Universitas Negeri Semarang, Semarang, 2017.

[9] Syah, A. K.., “Redesign Rangka Monocoque Bagian Bawah (Main Frame) Bus Listrik PT.MAB Dan Perencanaan Safety Factor Berbasis Software Invertor.,†Universitas Negeri Semarang, Semarang, 2020.

[10] Widodo, D. R., “Cost Report Analysis Pada Material Dan Proses Manufaktur Frame Kendaraan Formula Garuda 2016 (FG16) Garuda UNY Racing Team.,†Universitas Negeri Yogyakarta, Yogyakarta, 2018.

[11] Sumarni, M.Pd., D, Model Penelitian Pengembangan (R&D) Lima Tahap (MANTAP). Yogyakarta: Universitas Islam Negeri Sunan Kalijaga Yogyakarta, 2019.

[12] Dwi Jatmoko, “Modification of the Four-Step Motorcycle Camshaft Used in Making Salwa Cars (Go Card,†J. E-Komtek, vol. 5, no. 2, pp. 265–276, 2021.