The Effect of Printing Speed Variations on Dimensional Stability of 3D Printing Results Made from Waste Bottle Filament

##plugins.themes.academic_pro.article.main##

Abstract

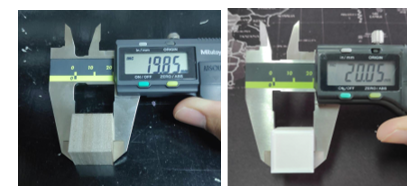

3D printers have grown in popularity in recent years because of their ability to print objects quickly and easily. The material used to print objects on a 3d printer is called the filament. Using recycled materials to produce 3D printer filament is gaining popularity in the 3D printing industry. One material that can be recycled to make filament is waste bottles of the Polyethylene Terephthalate (PET) type. This research was conducted to see the effect of printing speed on object dimensional stability. In this study used an experimental method by designing variations in printing speed on a 3D printer and using waste bottle filament as raw material. Each variation of printing speed was repeated five times and the dimensions were measured using a micrometer. The results showed that printing speed affects the dimensional stability of 3D printing results from waste bottle filament.

##plugins.themes.academic_pro.article.details##

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

[2] M. K. J. E. Exconde, J. A. A. Co, J. Z. Manapat, and E. R. Magdaluyo, “Materials selection of 3D printing filament and utilization of recycled polyethylene terephthalate (PET) in a redesigned breadboard,†Procedia CIRP, vol. 84, pp. 28–32, 2019, doi: 10.1016/j.procir.2019.04.337.

[3] I. Tylman and K. Dzierzek, “Filament for a 3D Printer from Pet Bottles-Simple Machine,†Int. J. Mech. Eng. Robot. Res., vol. 9, no. 10, pp. 1386–1392, 2020, doi: 10.18178/ijmerr.9.10.1386-1392.

[4] M. Bustos Seibert, G. A. Mazzei Capote, M. Gruber, W. Volk, and T. A. Osswald, “Manufacturing of a PET Filament from Recycled Material for Material Extrusion (MEX),†Recycling, vol. 7, no. 5, 2022, doi: 10.3390/recycling7050069.

[5] V. E. Alexopoulou, I. T. Christodoulou, and A. P. Markopoulos, “Effect of Printing Speed and Layer Height on Geometrical Accuracy of FDM-Printed Resolution Holes of PETG Artifacts †,†Eng. Proc., vol. 24, no. 1, 2022, doi: 10.3390/IECMA2022-12887.

[6] A. A. Ansari and M. Kamil, “Effect of print speed and extrusion temperature on properties of 3D printed PLA using fused deposition modeling process,†Mater. Today Proc., vol. 45, no. xxxx, pp. 5462–5468, 2021, doi: 10.1016/j.matpr.2021.02.137.

[7] A. Ouballouch, R. El Alaiji, S. Ettaqi, A. Bouayad, M. Sallaou, and L. Lasri, “Evaluation of dimensional accuracy and mechanical behavior of 3D printed reinforced polyamide parts,†Procedia Struct. Integr., vol. 19, pp. 433–441, 2019, doi: 10.1016/j.prostr.2019.12.047.

[8] A. R. Muhammad, R. R. Sakura, D. Dwilaksana, Sumarji, and M. Trifiananto, “Layer Height, Temperature Nozzle, Infill Geometry and Printing Speed Effect on Accuracy 3D Printing PETG,†R.E.M. (Rekayasa Energi Manufaktur) J., vol. 7, no. 2, pp. 81–88, 2022, doi: 10.21070/r.e.m.v7i2.1649.