Studi Analisis Sistem Induksi Udara Mobil Toyota Avanza K3-VE Dengan Scanner Launch Thinkdiag Easydiag 4.0

##plugins.themes.academic_pro.article.main##

Abstract

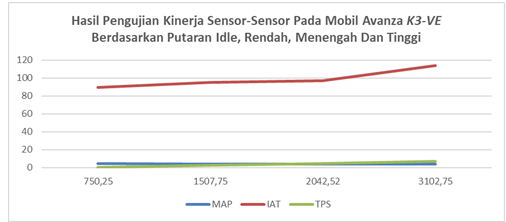

Testing the air induction system on the toyota avanza K3-VE car with the thinkdiag easydiag 4.0 launch scanner aims to test the air induction system with car media whether the sensors and air induction system contained in the media work well. The method used in this research is to use a descriptive research method. The data collection used in this study aims to strengthen the results of research based on a theory, ideas of experts and observations. Based on the results of the tests that have been carried out on the Toyota Avanza K3-VE car with the Thinkdiag Easydiag 4.0 launch scanner at stationary, low, medium and high rotations, namely: 1) speed of 750.25 Rpm, the IAT sensor reads 89.6 degree F, the MAP sensor is 4.2 Psi and the TPS sensor reads 0%, 2) speed 1507.75 Rpm IAT sensor reads 95 degree F, MAP sensor 3.62 Psi and TPS sensor reads 2.75%, 3) speed 2042.52 Rpm IAT sensor reads 96.8 degree F, MAP sensor 3.62 Psi and TPS sensor reads 4.31%, and a speed of 3102.75 Rpm the IAT sensor reads 114 degree F, the MAP sensor 3.77 Psi and the TPS sensor reads 6.67%, from the data obtained above it can be concluded that the sensor and air induction system on the Toyota Avanza K3-VE function properly and can be used for private vehicles. effective daily.

##plugins.themes.academic_pro.article.details##

References

[2] L. P. Z. M. Soares and T. D. Putra, “Pengaruh Perbandingan Campuran Udara Dan Bahan Bakar Pada Main Jet Karburator Terhadap Performance Motor Bakar Bensin,†Proton, vol. 10, no. 1, pp. 30–34, 2018, doi: 10.31328/jp.v10i1.805.

[3] T. Sugiarto, D. S. Putra, W. Purwanto, and W. Wagino, “Analisis Perubahan Output Sensor Terhadap Kerja Aktuator pada Sistem EFI (Electronic Fuel Injection),†INVOTEK J. Inov. Vokasional dan Teknol., vol. 18, no. 2, pp. 91–100, 2018, doi: 10.24036/invotek.v18i2.418.

[4] S. Rizal, “SISTEM INDUKSI UDARA (AIR INDUCTION SYSTEM) DAN TROUBLESHOOTING PADA MESIN TOYOTA VIOS 1NZ-FE,†Tugas Akhir, p. 74, 2013.

[5] J. P. Z. Furqon, Pemeliharaan Mesin Kendaraan Ringan SMK/MAK Kelas XI: Program Keahlian Teknik Otomotif. Kompetensi Keahlian Teknik Kendaraan Ringan Otomotif (Edisi Revisi)., Revisi. Penerbit Andi, 2021.

[6] I. Munthe, “Perbandingan Emisi Gas Buang Mesin Berteknologi VVT-I dan Non VVT-i,†Piston, vol. 4, no. 1, pp. 13–21, 2019.

[7] T. Sugiarto, B. Amin, W. Purwanto, A. Arif, and D. S. Putra, “Peningkatan Kompetensi Guru Dan Siswa SMK Melalui Pelatihan Kompetensi Kejuruan Teknologi Otomotif,†INVOTEK J. Inov. Vokasional dan Teknol., vol. 19, no. 1, pp. 25–34, 2019, doi: 10.24036/invotek.v19i1.439.

[8] I. W. Handoko and N. A. Hasibuan, “Sistem Pakar Deteksi Kerusakan Map Sensor Pada Mobil Honda,†Konf. Nas. Teknol. Inf. dan Komput., vol. I, pp. 167–170, 2017.

[9] Fitria, “PENGARUH ENGINE REMAP TERHADAP BEBERAPA PARAMATER OPERASI MOBIL BERBAHAN BAKAR LGV,†J. Chem. Inf. Model., vol. 53, no. 9, pp. 1689–1699, 2013.

[10] H. Nasrullah, B. Wilantara, Parikhin, and B. Prastaji, “Pengujian Kabin Sirkulasi Pendingin pada Trainer Simulator Air Conditioning Mobil,†J. E-Komtek, vol. 4, no. 2, pp. 184–190, 2020, doi: 10.37339/e-komtek.v4i2.407.